Measurement Facilities and Equipment

Anechoic chamber

The facility include an anechoic chamber, in which free space conditions are ensured by covering walls, ceiling and floor with microwave-absorbing material to suppress reflections that could deteriorate the measurement results. The chamber allows for antenna parameters, radar cross section, electromagnetic interference, and system tests and measurements over a wide frequency range.

The chamber has dimensions of 6.7 m x 3 m x 2.5 m, whereas the distance between the antennas is equal to 4 m. The chamber is equipped with:

- Mitsubishi Robotic Arm, which can be utilized for measurement of fully 3-D antenna radiation patterns

- Rohde & Schwarz ZNB40 Vector Network Analyzer 10 MHz – 40 GHz

- Reference horn antennas operating up to 40 GHz

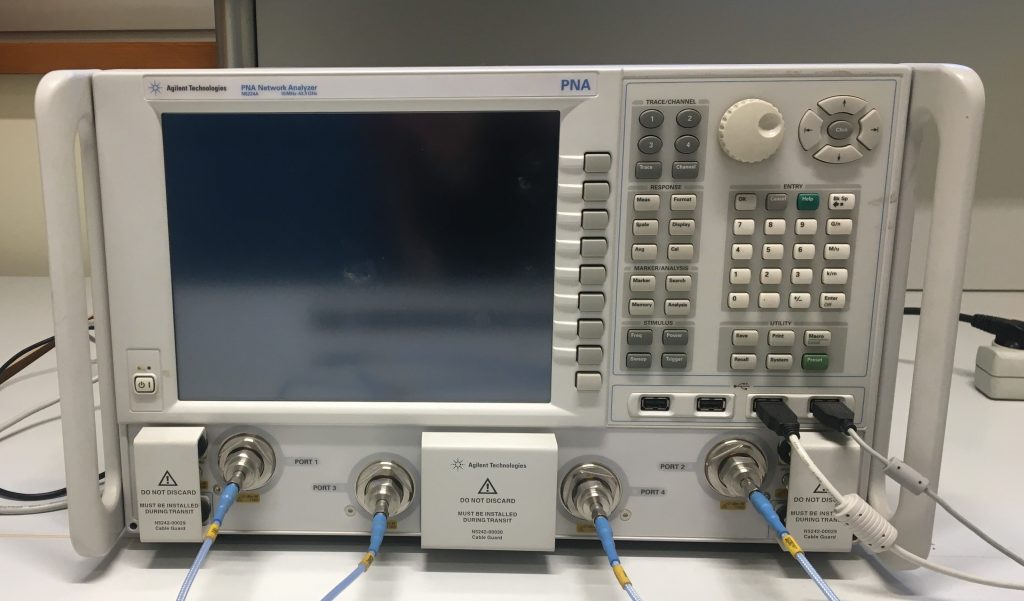

Agilent Technologies 4-port PNA Network Analyzer N5224A 10 MHz – 43.5 GHz

Detailed information can be found under the link:

Rohde & Schwarz SMF 100A Signal Generator 100 kHz – 43.5 GHz

Detailed information can be found under the link:

https://www.rohde-schwarz.com/no/product/smf100a-productstartpage_63493-8447.html

Rohde & Schwarz FSW Signal & Spectrum Analyzer 2 Hz – 85 GHz

Detailed information can be found under the link:

https://www.rohde-schwarz.com/ca/product/fsw-productstartpage_63493-11793.html

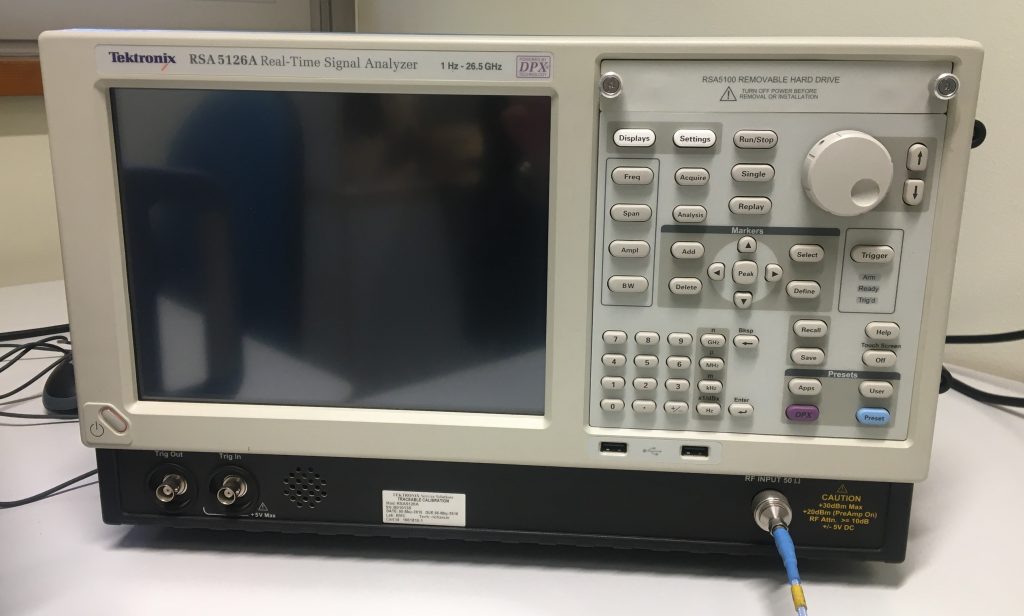

Tektronix RSA 5126A Real-Time Signal Analyzer 1 Hz – 26.5 GHz

Detailed information can be found under the link:

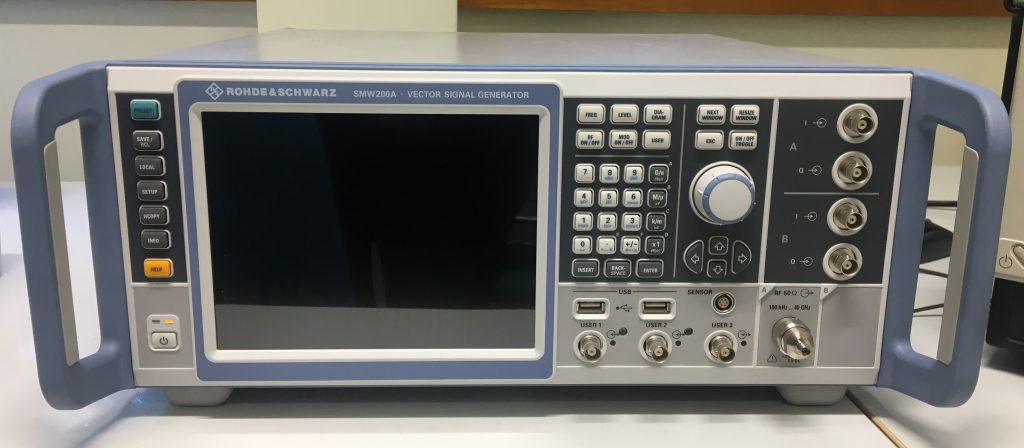

Rohde & Schwarz SMW200A Vector Signal Generator 100 kHz – 40 GHz

Detailed information can be found under the link:

https://www.rohde-schwarz.com/ae/product/smw200a-productstartpage_63493-38656.html

Keysight 33500B Series Trueform Waveform Generator 30 MHz

Detailed information can be found under the link:

https://www.keysight.com/zz/en/assets/7018-05928/data-sheets/5992-2572.pdf

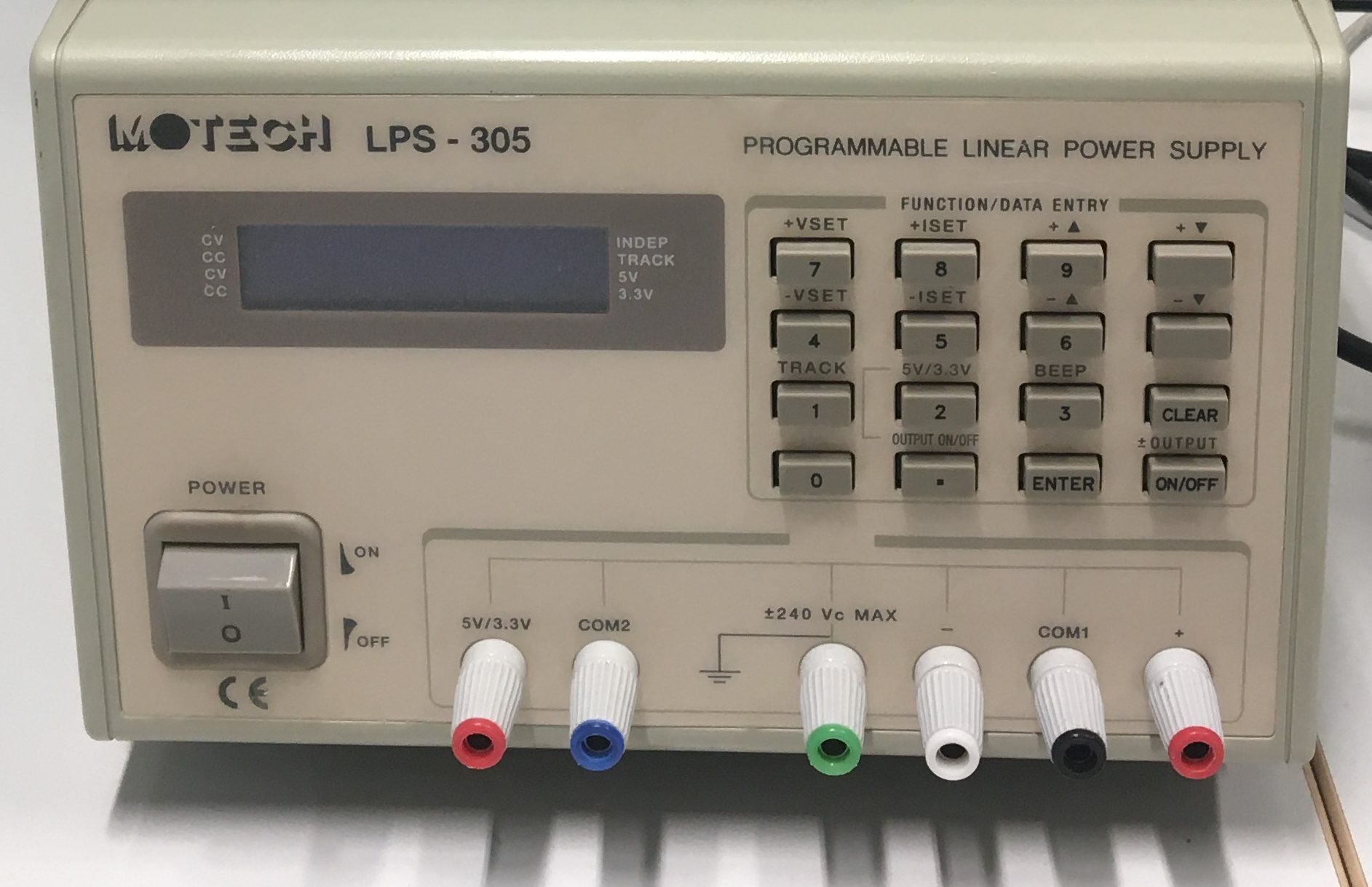

Programmable Linear Power Supply MOTECH LPS-305

Detailed information can be found under the link:

https://www.manualslib.com/manual/707745/Motech-Lps-305.html#product-LPS%20305

Hewlett Packard Spectrum Analyzer 8563A 9KHz – 26.5 GHz

Detailed information can be found under the link:

http://www.testequipmenthq.com/datasheets/Keysight-8563A-Datasheet.pdf

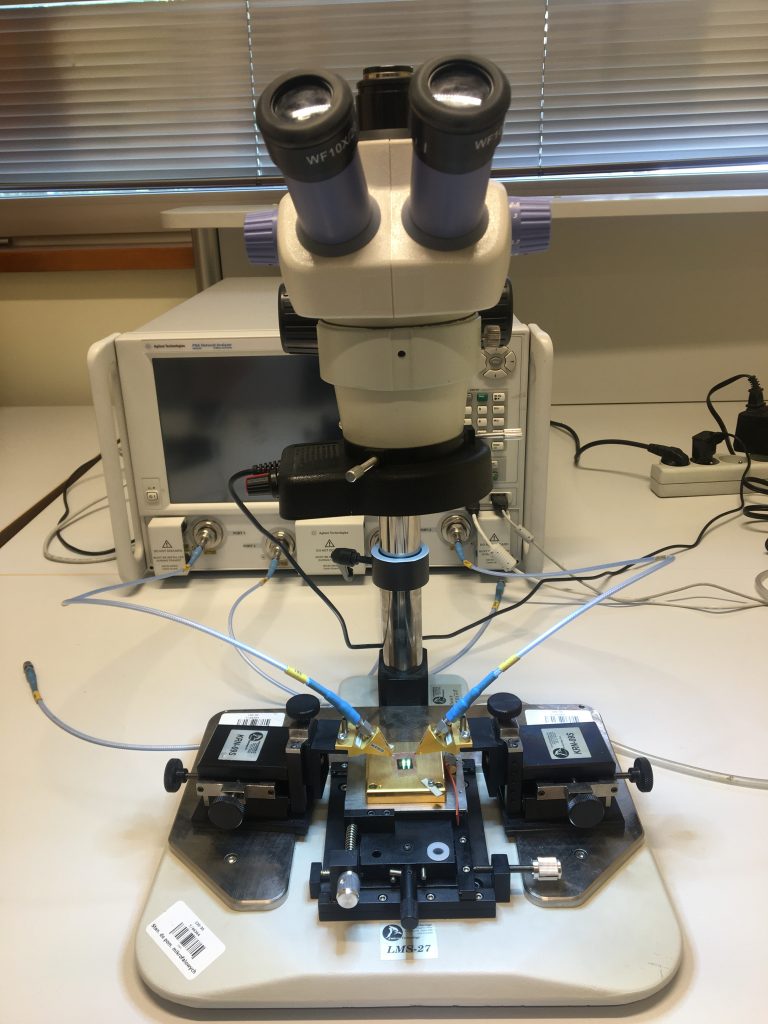

Laboratory Microprobing Station

A rugged and basic RF (and DC) probe station for research of advanced active and passive components and also for educational training of university students in the discipline of microwave microprobing. Complete with magnetic mount ball bearing microprobing positioners and GGB Industries RF microprobes. Binocular stereo zoom microscope with 10X/30X magnification (included wide field eyepieces), Fluorescent ring Illuminator, precision x-y stage with vacuum hold down and Z-lift. Vacuum Pump included.

The measurement station is additionally equipped with:

- Z-probes Z040-K3N-GSG-650 (4 pieces)

- Z-probes Z040-K3N-GSG-200 (3 pieces)

- Z-probes Z40-XD-GSGSG-200 (3 pieces)

- Z-probe Z20-XD-GSSG-250 (1 piece)

More information regarding the Microprobing Station can be found under the link:

https://www.rikei.co.jp/wp/wp-content/uploads/2016/10/pdf1.pdf

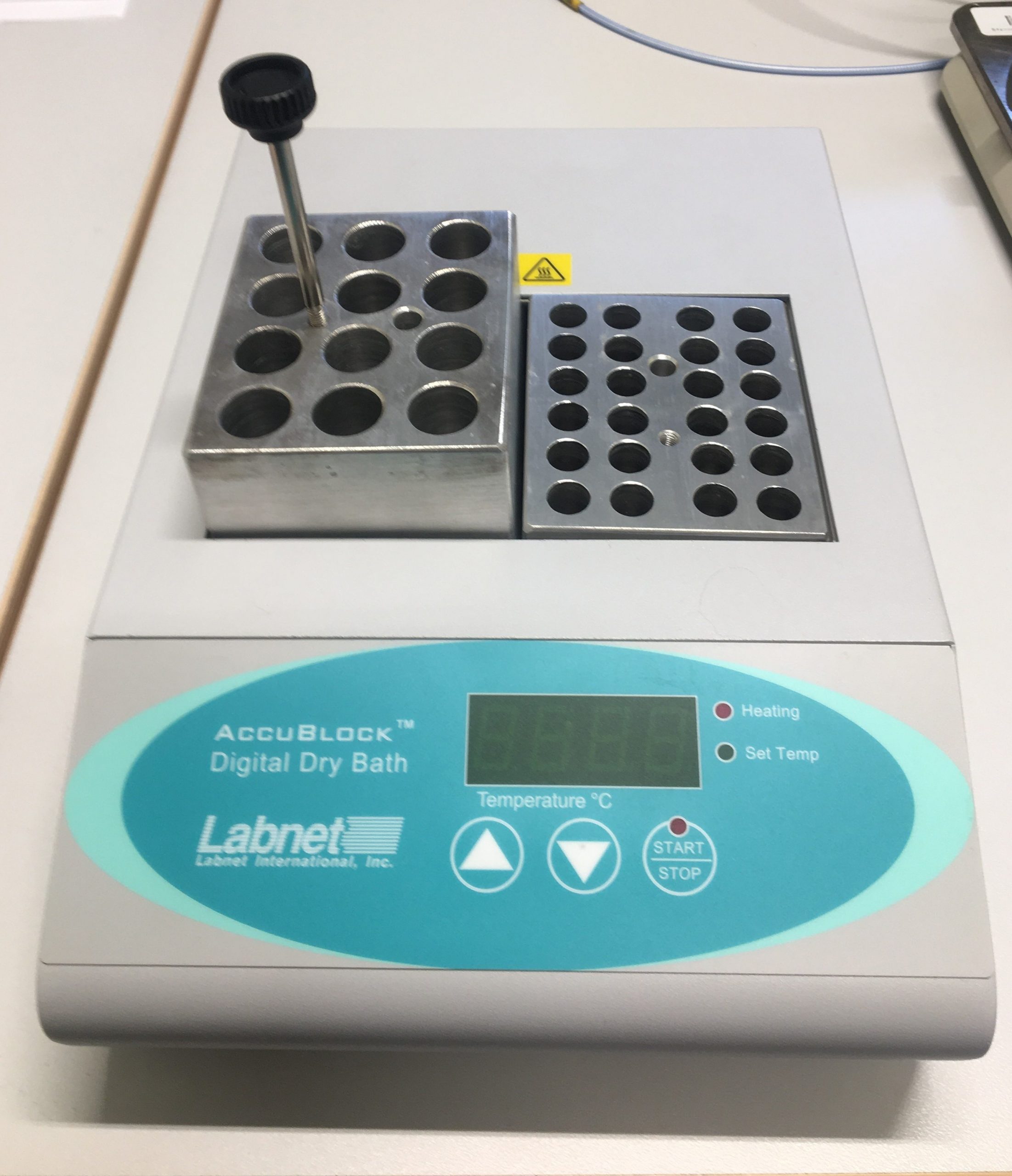

Digital Dry Bath Labnet D1200

Labnet Vortex Mixer

Students’ Labs

The students’ Lab are equipped with all basic equipment, such as VNAs, spectrum analyzers and sources, allowing to acquaint students with principles of microwave electronics.

Manufacturing Facilities and Equipment

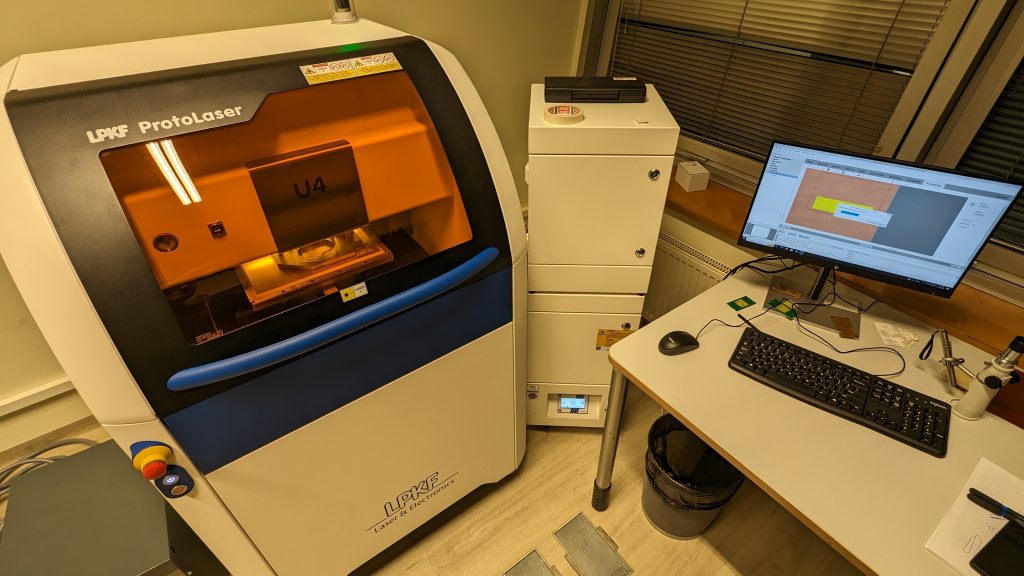

LPKF ProtoLaser U4

The LPKF ProtoLaser U4 can structure or cut diverse materials quickly and cleanly. The laser wavelength used makes the UV laser a truly multifunctional tool. A UV laser beam can cut individual boards out of large boards with high precision and no stress, drill holes and microvias, and create openings in solder masks. It can cut and structure LTCCs, fired ceramics, ITO/TCO substrates, delicate prepregs, and laminated materials like FR4- or RF-specific substrates.

The processing of various materials is supported by the CircuitPro Advanced software. An extensive materials library supplies the laser parameters for key materials. Because the ProtoLaser U4 works without material contact, tooling costs are a thing of the past. Micro

material processing thus benefits from the fine laser beam diameter, the extremely precise focusing along the Z-axis, and the exact control of the processing positions

More detailed information about the printer can be found under the link: https://www.lpkf.com/en/industries-technologies/research-in-house-pcb-prototyping/products/lpkf-protolaser-u4

LPKF Contac S4

Interconnection of two or more layers is an indispensable part of PCB prototyping. The compact LPKF Contac S4 with six baths reliably performs this task: the board is passed through each stage of a bath cascade. This yields reliable copper layers on the surfaces of all existing vias, even in multilayer boards. The Contac S4 can process up to eight layers with a maximum aspect ratio of 1:10 (hole diameter to PCB thickness). The LPKF Contac S4 offers a subsequent tin bath step for surface protection and improved solderability.

More detailed information about the printer can be found under the link: https://www.lpkf.com/en/industries-technologies/research-in-house-pcb-prototyping/products/lpkf-contac-s4

Vacuum Exposure Unit Bungard Hellas

It is a precision vacuum exposure unit for double-sided contact exposure of photocoated base material, print films and more. With the vacuum Hellas unit you can process all photosensitive products with spectral sensitivity in the near UV range (360-400nm). These are especially positive or negative photo-coated PCBs, printing plates made of nylon, aluminum, steel and diazo and transfer films. Dimensions (LxWxH): 620 x 650 x 240 mm³, max. Exposure area: approx. 570 x 300 mm².

Chemical Etching Station

The chemical etching is performed with the use of sodium persulfate as the etchant solution. The chemical etching station allows for temperature control of the etchant solution and uses an air pump with a curtain to obtain an even etching process within the volume of the tank.

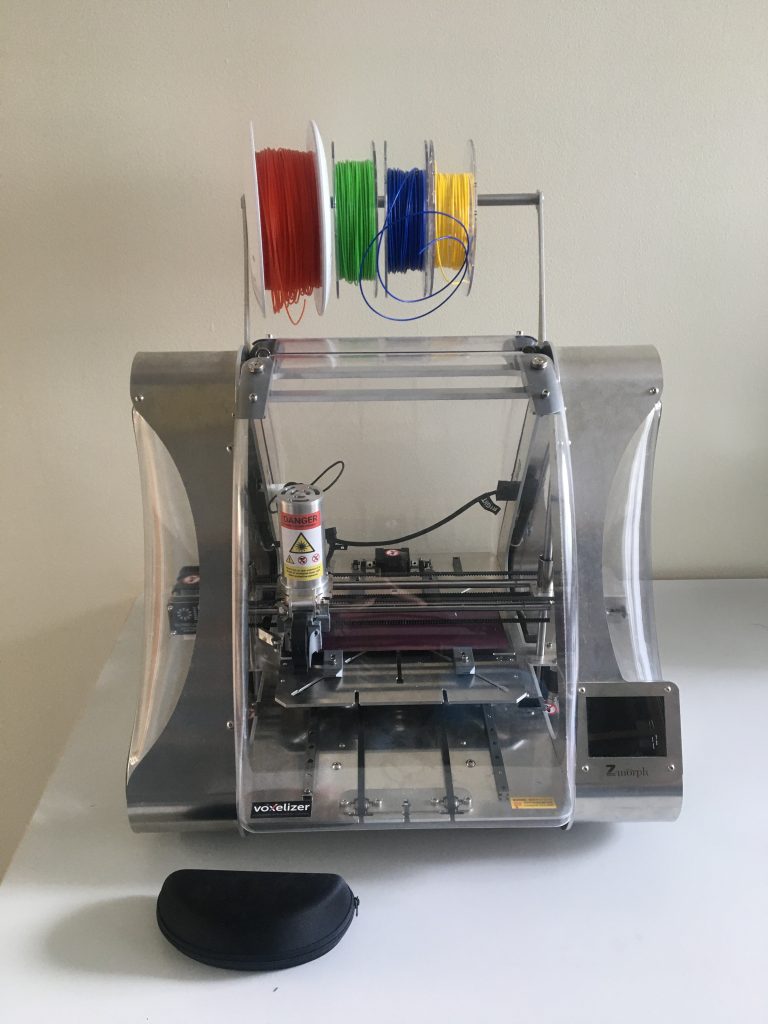

ZMorph VX Multitool 3D Printer

The ZMorph VX product is a multitool 3D printer. It has a system of interchangeable toolheads, designed to perform 3D model prints in Fused Filament Fabrication (FFF) technology, CNC milling, and laser engraving and cutting. ZMorph VX together with Voxelizer software provides a complete environment for moving 2D and 3D projects from monitor screen to reality. The device can operate independently or with an external computer on which the control software is installed. In this case, a USB connection or LAN connection is required. The control software is available on the manufacturer’s website https://voxelizer.com The device is equipped with a built-in touch screen LCD panel which serves as a graphical interface for operation in standalone mode. The LCD panel has a port for SD cards on which it is possible to deliver ready-made executive files (G-code files). Files can also be sent to the device’s internal memory via a computer.

More detailed information about the printer can be found under the link: https://zmorph3d.com/product/zmorph-vx

Orginal Prusa SL1S and Prusa Curing and Washing Machine

The original Prusa SL1S 3D printer features a high-resolution 5.5” LCD display and silent trinamic drivers, SL1 is able to reach a minimum layer height of 0.01 mm. With the recommended layer height of 0.025-0.1 mm and print area size of 120 x 68 x 150 mm detailed objects can be printed. The Original Prusa SL1 3D printer is built around a rigid, heavy aluminium body, which minimizes vibrations and ensures the best possible printing performance. The acrylic glass lid prevents UV light leakage and the tilt platform has a small ridge to stop light resin spills. The SL1 is compatible with a wide range of different resins. Thanks to non-proprietary technology used, the running costs are low, and the printer maintenance is easy. The Original Prusa SL1 is fully compatible with PrusaSlicer allowing for automatic support generation, library of tested resins, network printing and many other advanced features.

After printing an object from resin, it is highly recommended to wash it in isopropylalcohol and cure the surface using UV light. The CURING AND WASHING MACHINE is a 2-in-1 device, and it takes care of both tasks. It can even automatically select the right mode. Complete specification of the printer can be found under the link: https://www.prusa3d.com/original-prusa-sl1/#_ga=2.210906387.76871220.1599123271-1946283413.1595492416

Original Prusa i3 MK4

The MK4 is the latest edition of our flagship 3D printing workhorse. It combines the reliability and safety features of its predecessors with high-speed performance enabled by Input Shaper support. It brings plenty of new features like a perfect smooth first layer thanks to the Loadcell sensor (no manual adjustments needed).

The next-gen extruder (Nextruder) and 32-bit connected platform provide many quality-of-life improvements like remote printing, quick-swap nozzles, and customizable UI with a one-click printing option, and much more.

The full feature list of the printer is available under the link: https://www.prusa3d.com/product/original-prusa-mk4-2/

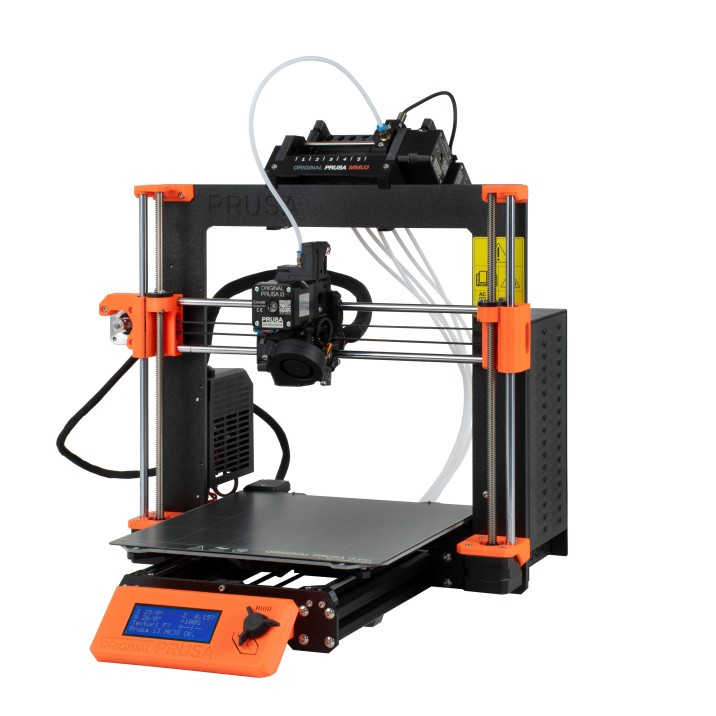

Original Prusa i3 MK3S+ 3D printer with Multi Material Upgrade 3

The Original Prusa i3 MK3S+ is the last version of our award-winning MK3 3D printer line. We have upgraded the MK3S with a brand new SuperPINDA probe for improved first layer calibration, added high-quality bearings and made various useful design tweaks.

The Original Prusa MMU3 is our latest solution for printing with up to five filaments at the same time with high speed and low waste. As an add-on for the Original Prusa i3 MK3S+ and MK4, it enables automatic switching between loaded materials. MMU3 is fully supported in PrusaSlicer by an easy multi-material painting tool, and it offers efficient and filament-saving color printing to everybody.

The full feature list of the printer is available under the link: https://shop.prusa3d.com/en/3d-printers/181-original-prusa-i3-mk3s-3d-printer.html#

Assembly and Testing Station

The assembly and testing station include the following equipment:

- Microscope

- Soldering stations Pace and XXXX

- DC Power Supply 0-30V, 0-5A

- Multimeter PiCOTEST M3500A